Since 2008, Teknipure has been committed to developing, manufacturing, and distributing to our customers the best in consumable contamination solutions. We listen to your needs (as well as the needs of the market in general) and provide products designed to prevent, control, and remove contamination in an effective and efficient manner. You won’t find more stringent production standards than the ones we adhere to.

In a sea of white wipers, one white wiper looks like another white wiper… until you look closer. And on top of that, one sterile wiper might look like another but not wipe the same. Teknipure brings over two decades of cleanroom design and operation experience to our development of engineered materials that deliver specialized functionality for each task. Whether absorbing fluids, removing API and residuals, or applying fluids, our sterile wipers function to improve efficiency, quality, and reduce defects in your aseptic processes in ways other wipers cannot.

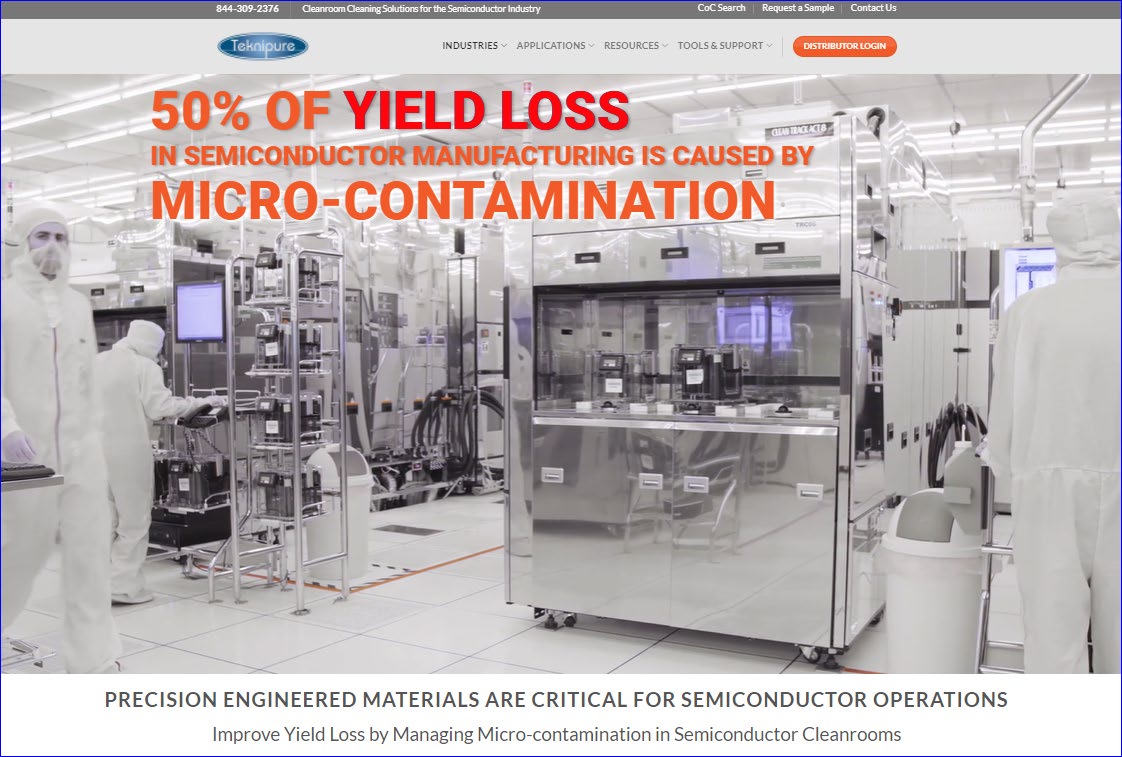

In our last newsletter, we shared with you that we’ve added a new section to our website called “Industries”, which highlights our products for semiconductor, medical device, and pharmaceutical manufacturing. In this newsletter, we will focus on the semiconductor section.

Teknipure Solutions for The Semiconductor Industry

50% of yield loss in the manufacturing of semiconductors comes from micro-contamination. When you are able to keep adulteration at bay and optimize yield, you gain the competitive advantage over others in the industry. We provide the best consumable contamination solutions for the semiconductor industry.

On our new Semiconductor Manufacturing section of the website, you will find in-depth information about the following topics:

Fabrication

We know fabricating semiconductor wafers can involve 1,000 or more process steps. And if your equipment, process, or workers bring any sort of contamination into production, costly defects and yield issues can result.

Meeting market demand and maximizing your profit depend upon the highest optimization of manufacturing levels, and Teknipure products decrease yield loss by controlling sources of micro-contamination.

Lab & Tool Maintenance

The key to success in your semiconductor production operation is to manage and control contamination, which brings other benefits also. Maintaining your equipment is essential to maximizing uptime and minimizing yield loss. The interior of tools can retain foreign material (FM), and that can stop processing for an unknown amount of time while the issues are researched and solved. The right wipers will remove FM and ensure tools are properly cleaned and maintained, which means uptime and quality are increased.

Gowning Rooms

Your gowning rooms are where yield loss can start. Within the semiconductor industry, problems starting in this area of fabrication facilities results in billions of dollars in lost revenue. Make sure your controlling of micro-contamination begins in the gowning room. The exterior surfaces of PPE and any other items that are brought into critical production areas must be decontaminated prior to entry. The right Teknipure wipers, used before unpackaging, effectively and efficiently remove any surface contaminants before they have a chance to latch onto workers entering the cleanroom.

Specialty Applications

Whatever specialty applications you need consumable contamination solutions for, we’ve got the products. If you need solutions for rough surfaces, ESD (electrostatic dissipative) sensitive areas, high-volume liquid absorption, or high-efficiency dry particulate/residue removal, Teknipure offers the highest quality wipers to get the job done.

Semiconductor Trends Expected in 2022

We’ve all learned over the past few years how essential semiconductors are, between supply shortages and production issues brought about by COVID-19. In 2022, the industry is projected to be about $600 billion globally, even though major manufacturers amount to only a handful.

Did you know that not having just one, individual chip costing $1 could result in not being able to manufacture an appliance or device that sells for thousands of dollars? In fact, analysis of the semiconductor industry by Deloitte found that shortages of chips since the start of COVID-19 caused over $500 billion in lost revenue – $210 billion in 2021 alone vanished in vehicle sales due to the deficiency. The following 4 trends, explored and published by Deloitte, are expected to be key in the industry this year:

![]()

- We expect the global industry to grow 10% in 2022 to over US$600 billion for the first time ever. Chips will be even more important across all industries, driven by increasing semiconductor content in everything from cars to appliances to factories, in addition to the usual suspects—computers, data centers, and phones.

- We expect shortages and supply chain issues to remain front and center for the first half of the year, hopefully easing by the back half, but with longer lead times for some components stretching into 2023, possibly well into 2023.

- The ongoing talent shortage will be made even more severe by the addition of increased semiconductor manufacturing facilities outside Taiwan, China, and South Korea. The higher demand for software skills required to program and integrate chips into fast-growing markets will further exacerbate the shortage.

- Finally, we expect the digital transformation within the industry to continue and accelerate. Nearly three out of five chip companies have already begun their transformation journey. Still, over half of those are modifying their transformation process as they go, in response to various pressures.

Teknipure is a Proud Member of the

To learn more or to request technical data sheets, call us at 844.309.2376 or email us at Info@Teknipure.com. You may request samples or find quality certificates online.